Prevent Equipment Failure and Costly Downtime

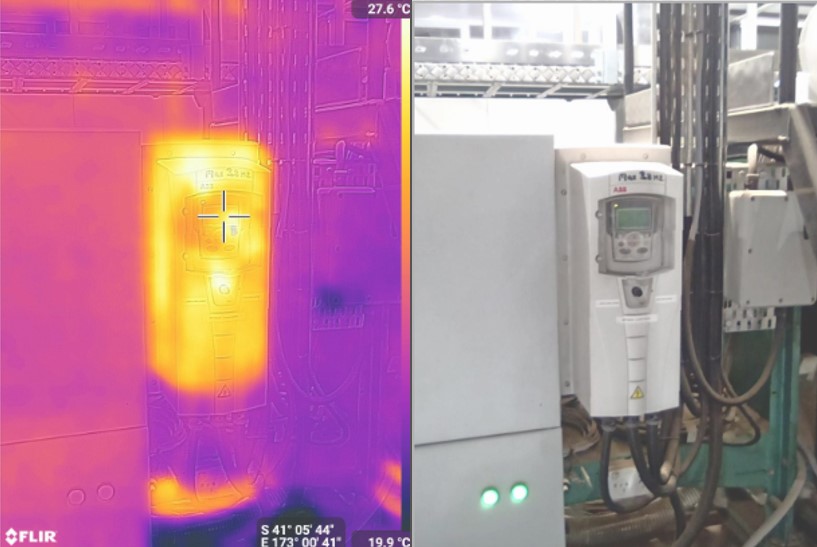

Electrical thermal testing is a crucial practice for maintaining safe and reliable electrical systems. By using infrared cameras, we can capture heat distribution images of electrical components, allowing us to assess maintenance requirements without disrupting normal operations. This will reduce the potential for unexpected equipment failure, accidents, and costly downtime.

How we do it

Our certified technicians follow a non-disruptive process for electrical thermal imaging:

- Inspection: We inspect electrical components, including switch gear, motor bearings, and cabling.

- Thermo-graphic Imaging: Using infrared cameras, we capture thermo-graphic images.

- Analysis: Our experts analyse the images to identify irregularities and potential issues.

Applications

Locating Issues

- Loose Connections: Identify loose or faulty connections.

- Overheating Components: Locate hot spots in switchboards and other equipment.

- Winding Faults: Detect thermal faults in motor windings.

- Poor Cabling: Identify areas where cabling may be compromised.

Switchboard Inspections

Insurance companies increasingly require switchboard thermal imaging. Our detailed reports meet insurance compliance standards and include:

- Thermo-graphic Images: Clear documentation of irregularities found during inspections.

- Precision: Accurate results using advanced infrared technology.

Reliability Enhancement

Electrical thermal testing enhances product reliability by:

- Detecting potential issues early.

- Preventing costly breakdowns.

- Minimising downtime.

Reporting

Our comprehensive reports include:

- Image Documentation: Thermo-graphic images with annotations.

- Detailed Findings: Clear explanations of irregularities.

- Insurance Compliance: Reports that meet insurance company requirements.